■ Overview

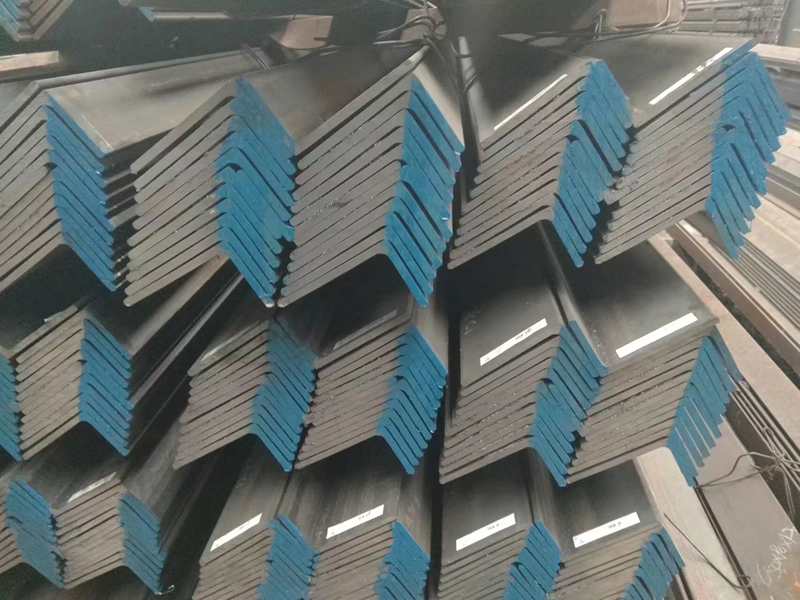

Steel angles s275jr,angle bars s275jr,L-profiles s275jr are used for various purposes in a number of industries such as steel frames,brackets,trim,reinforcements and many other uses.Xinsteel as top 1 steelholder in Henan Province in China keeps ten thousand tons hot rolled high strength steel angles in warehouses.

■ Full Data

Technical Requirements & Additional Services:

♦ Low temperature impacting test

♦ Rolling under standard NACE MR-0175 (HIC+SSCC)

♦ Ultrasonic test under EN 10160,ASTM A435,A577,A578

♦ Issued Orginal Mill test certificate under EN 10204 FORMAT 3.1/3.2

♦ Shot blasting and Painting,Cutting and welding as per end user’s demands

♦ Low temperature impacting test

♦ Rolling under standard NACE MR-0175 (HIC+SSCC)

♦ Ultrasonic test under EN 10160,ASTM A435,A577,A578

♦ Issued Orginal Mill test certificate under EN 10204 FORMAT 3.1/3.2

♦ Shot blasting and Painting,Cutting and welding as per end user’s demands

■ Techicals

►Mechnical property for S275JR carbon steel angles:

| Thickness (mm) | |||||||||

| S275JR | ≤ 16 | > 16 ≤ 40 | > 40 ≤ 63 | > 63 ≤ 80 | > 80 ≤ 100 | > 100 ≤ 150 | > 150 ≤ 200 | > 200 ≤ 250 | > 250 |

| Yield strength (≥Mpa) | 275 | 265 | 255 | 245 | 235 | 225 | 215 | 205 | 205 |

| < 3 | ≥ 3 ≤ 100 | > 100 ≤ 150 | > 150 ≤ 250 | > 250 | |||||

| Tensile strength (Mpa) | 430-580 | 410-560 | 400-540 | 380-540 | 380-540 | ||||

►Chemical composition for S275JR mild steel angles (Ladle Analysis Max%)

| Main chemical elements composition of S275JR | |||||||

| Thickness(mm) | C | Si | Mn | P | S | N | Cu |

| T≤16 | 0.21 | ... | 1.50 | 0.035 | 0.035 | 0.012 | 0.55 |

| 16<T≤40 | 0.21 | ||||||

| 40<T | 0.22 | ||||||

+86 371 55057610

+86 371 55057610  inquiry@xsteelplate.com

inquiry@xsteelplate.com

Tel:+86 371 55057610

Tel:+86 371 55057610  Fax: +86 371 5505 7611

Fax: +86 371 5505 7611