■ Overview

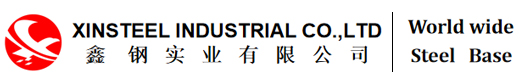

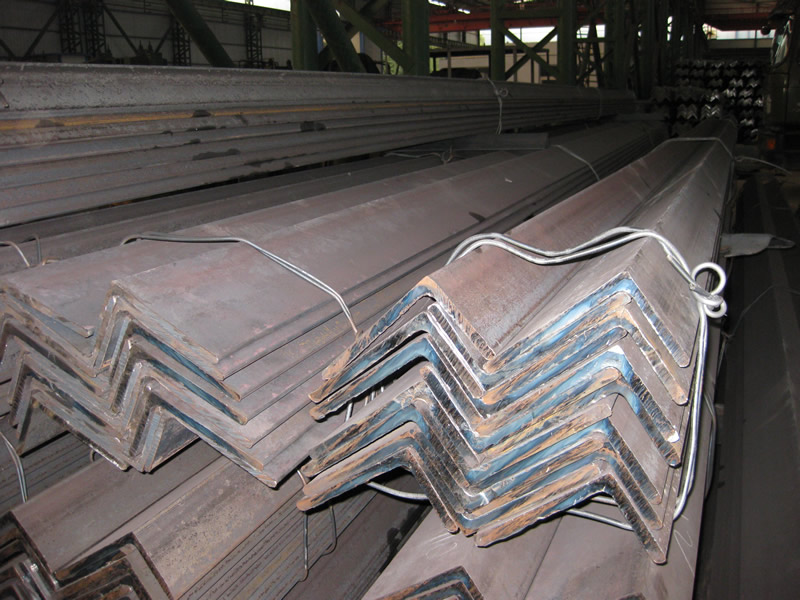

Shipyards use shipbuilding steel angles ASTM A131 Grade AH36 to construct tanks and vessels in ships cause A131 Grade AH36 ship steel angles owned the higher yield strength and tensile strength.Xinsteel group owned tens of stock warehouses in port cities in China,there are thousands tons of shipbuilding steel angle bars and sheets and buld flats in stock which are ready to ship on board.

■ Full Data

Technical Requirements & Additional Services:

♦ High tension test

♦ Z-Test (Z15,Z25,Z35)

♦ Low temperature impacting test

♦ Ultrasonic test under ASTM A435,A577,A578

♦ Cetificated by ABS,LR,GL,BV,DNV,KR,NK,CCS,RINA

♦ Issued Orginal Mill test certificate under EN 10204 FORMAT 3.1/3.2

♦ Shot blasting and Painting,Cutting and welding as per end user’s demands

♦ High tension test

♦ Z-Test (Z15,Z25,Z35)

♦ Low temperature impacting test

♦ Ultrasonic test under ASTM A435,A577,A578

♦ Cetificated by ABS,LR,GL,BV,DNV,KR,NK,CCS,RINA

♦ Issued Orginal Mill test certificate under EN 10204 FORMAT 3.1/3.2

♦ Shot blasting and Painting,Cutting and welding as per end user’s demands

■ Techicals

►Mechnical property for A131 Grade AH36 shipbuilding structual steel angles:

| Yield strength (≥Mpa) | Tensile strength (Mpa) | Elongation in ≥,% | |

| 355 | 490-620 | 200mm | 50mm |

| 19 | 22 | ||

►Chemical composition for A131 Grade AH36 ship steel angles (Heat Analysis Max%)

| Main chemical elements composition of A131 Grade AH36 | ||||||

| C | Si | Mn | P | S | Al (acid) min. | Nb |

| 0.18 | 0.10-0.50 | 0.90-1.60 | 0.035 | 0.035 | 0.015 | 0.02-0.05 |

| V | Ti | Cu | Cr | Ni | Mo | |

| 0.05-0.10 | 0.02 | 0.35 | 0.20 | 0.40 | 0.08 | |

+86 371 55057610

+86 371 55057610  inquiry@xsteelplate.com

inquiry@xsteelplate.com

Tel:+86 371 55057610

Tel:+86 371 55057610  Fax: +86 371 5505 7611

Fax: +86 371 5505 7611